Laser Welding Machine

Home - Products - Laser Welding Machine - Handheld Portable Fiber Laser Welding Machine with Auto Wire Feeder

Brand : ZLTECH

Model : ZLW-1000W / 1500W / 2000W / 3000W

Category : Laser Welding Machine

Payment : TT, Visa, Mastercard, Credit Cards, Paypal, Western Union

Supply Ability : 200 Sets / Month

Warranty : 3 Years

Description

Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. The hand-held welding gun replaces the previous fixed optical path, which is more flexible and convenient, realizes long-distance laser welding, and overcomes the limitation of the workbench stroke space.

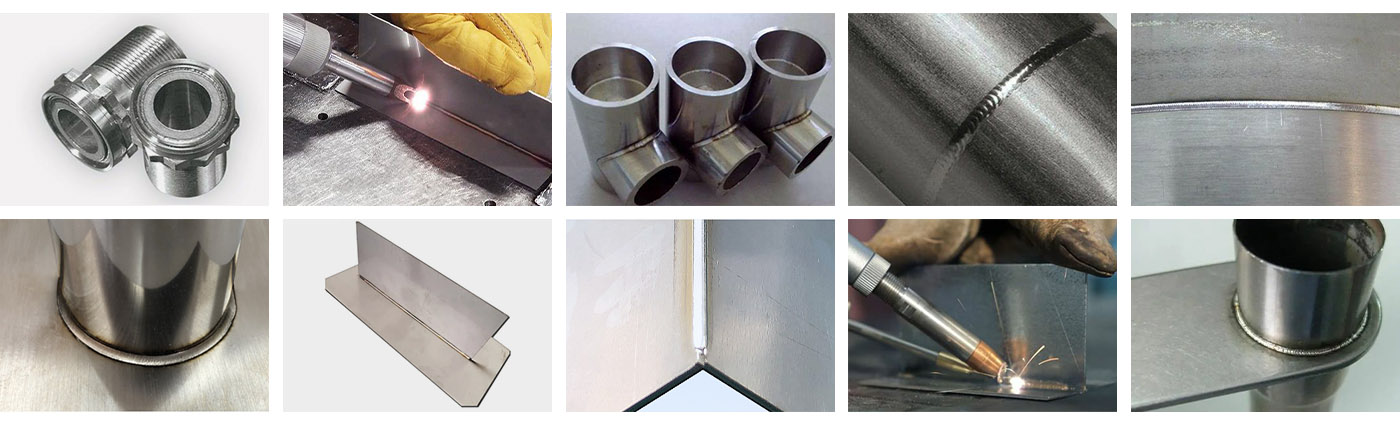

Laser welding machine can be used to weld Stainless steel, Carbon steel, Aluminum, Copper materials and many other metal materials.

Beautiful weld, fast speed, no consumables, no welding mark, no discoloration, no need to polish later. Can be configured with a variety of Angle nozzle to meet the welding needs of different products.

System characters

- Fast welding speed, higher welding efficiency than the traditional one

- Simple operation, can weld any position and any angle of the workpiece.

- Suitable for welding small batch and multi angle sheet metal and hardware parts

- Equipped with safety circuit to avoid false light, the operation is safer.

- Compact structure and small occupied space

- Integrated design, ultra long fiber transmission, overcoming the limitations of distance operation.

Advantages Introduction :

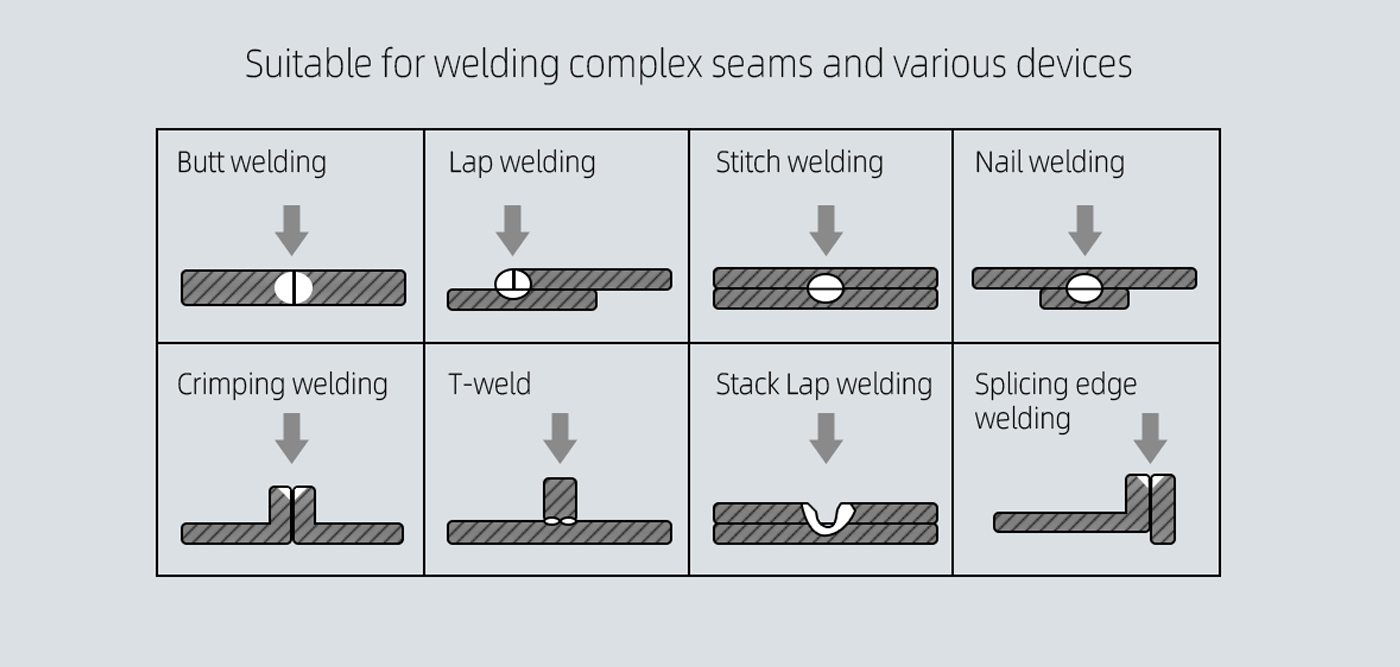

Various Welding Methods:

• The welding seam is smooth and beautiful, and the welding quality is good. It can realize spot welding, continuous spot welding, fish scale welding, full welding, and continuous full welding.

• Its advantages lie in the high aspect ratio, small width, small heat-affected zone and small deformation of the welding seam; fast welding speed, smooth and beautiful welding seam, no need for treatment or simple treatment after welding, high quality of welding seam, no pores, and accurate Control, small focusing spot, high positioning accuracy.

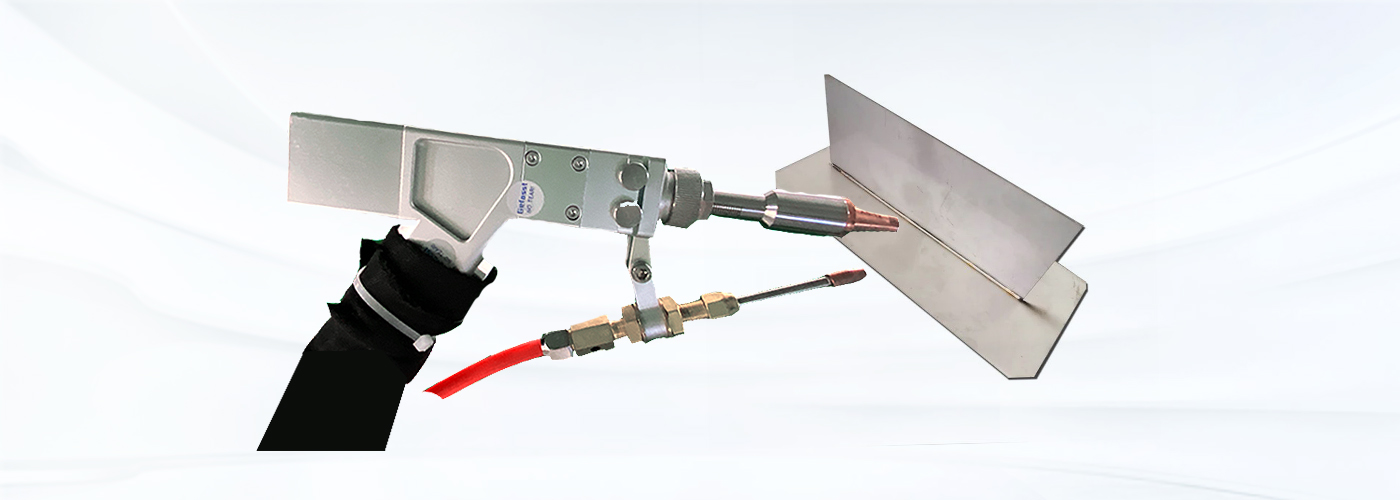

Laser Welding Head :

Smart high frequency swing welding head. Can be widely used in metal equipment, stainless steel home and other industries complex irregular welding process.

There are some different choice for you :

- Qilin brand

- Relfar brand

- Au3tech brand

- Chaoqiang brand

Laser Source :

Top brand fiber laser source Max, high power. The energy density is high, the heat input is low, the amount of thermal deformation is small.

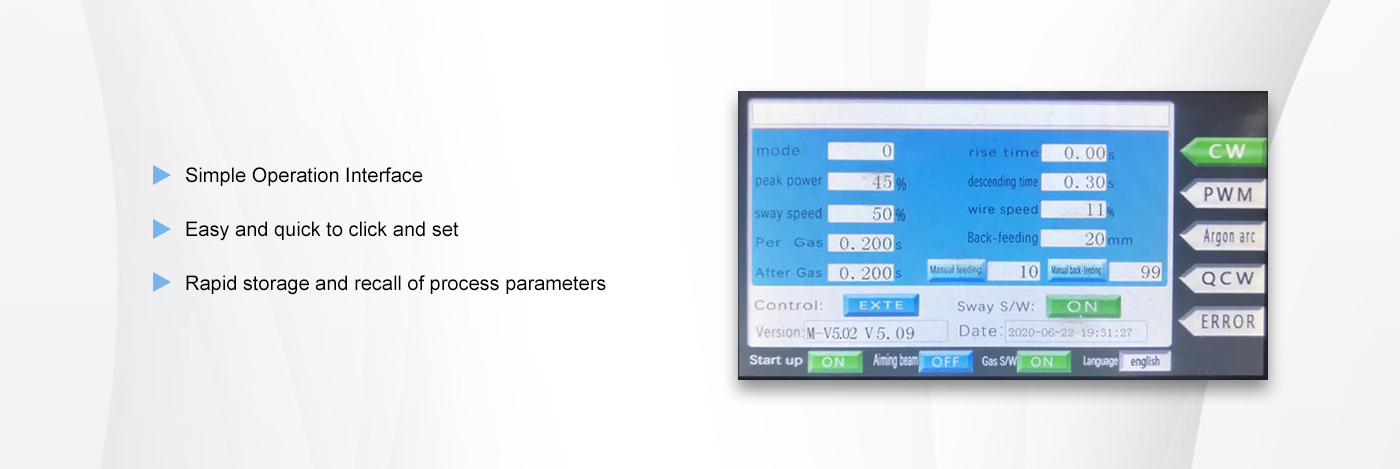

Intelligent Operating System :

• Adopt touch screen design, easy and quick to click and set, with real-time fault reading, feedback and alarm functions.

• There is a process parameter library, which can realize the rapid storage and recall of process parameters.

• Simple operation interface, humanized design, touch screen control, automatic layout optimization, to ensure high-speed operation of the whole machine.

Laser Wire filler Welding Process :

• Welding wire can be added during the welding process to solve the problem of excessive welding gap.

• Improved shaping of aluminum alloy laser welded surfaces, improved mechanical properties of joints, prevented cracks, and achieved less power.

This handheld laser welder will help you weld various shapes :

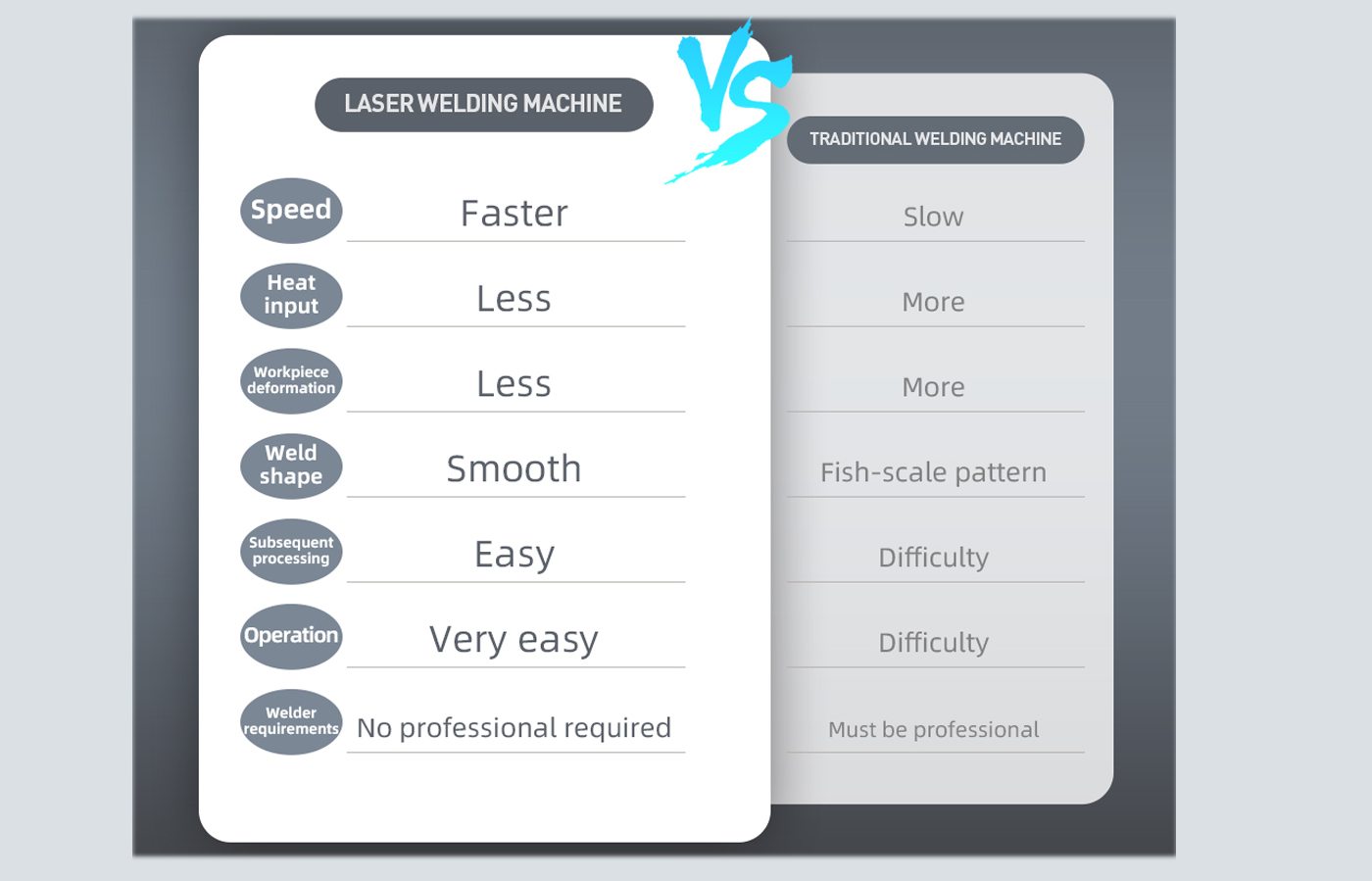

Difference between handheld laser welding machine and traditional welding machine :

Parameters

| Laser power | 1000w | 1500w | 2000w | 3000w |

| Conduction Type | Fiber laser | Fiber laser | Fiber laser | Fiber laser |

| Laser Frequency | 50-5000HZ | 50-5000HZ | 1064nm | 1064nm |

| Cooling Method | Water cooling | Water cooling | Water cooling | Water cooling |

| Total Power | 5.5kw | 7.7kw | 9.5kw | 14kw |

| Fiber Cable Length | 10m | 10m | 10m | 10m |

| Eectricity Requirements | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC |

| Welding Mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode |

| Filler wire dia | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm |

| Welding penetration | 3mm | 4mm | 5mm | 6mm |

| Working Temperature | 10 ℃-40℃ | 10 ℃-40℃ | 10 ℃-40℃ | 10 ℃-40℃ |

Strong Service Team

Quality Control & Testing

+86 18615585751

linda-service

C1, Floor 3, Shuntai Building, Gaoxin District, Jinan City, China