Apr. 08, 2022

Precautions for nozzles when cutting carbon steel with ZLTECH fiber laser cutting machine.

The nozzle of the laser cutting machine can assist in the ejection of gas, which can effectively prevent debris such as molten stains from rebounding upward, thereby protecting the focusing mirror. At the same time, it can control the gas diffusion area and size, which will affect the cutting quality of the laser cutting machine. At the same time, the aperture size of the nozzle will vary according to the thickness of the cutting material.

As the aperture of the nozzle is larger, the protection effect for the focusing lens is smaller. Therefore, a reasonable choice of the size of the nozzle aperture of the laser cutting machine can make production more efficient.

The effect for Carbon steel cut with fiber laser cutting machine is perfect. And for the high hardness of carbon steel material ,in order to avoid problems, we should to Maintenance our fiber laser cutting machine, especially the nozzles.

When fiber laser cutting machine cuts low carbon steel material, the fire beam is long, flat, and has fewer splits.If not, it will affects the working quality and the effect of cutting section.

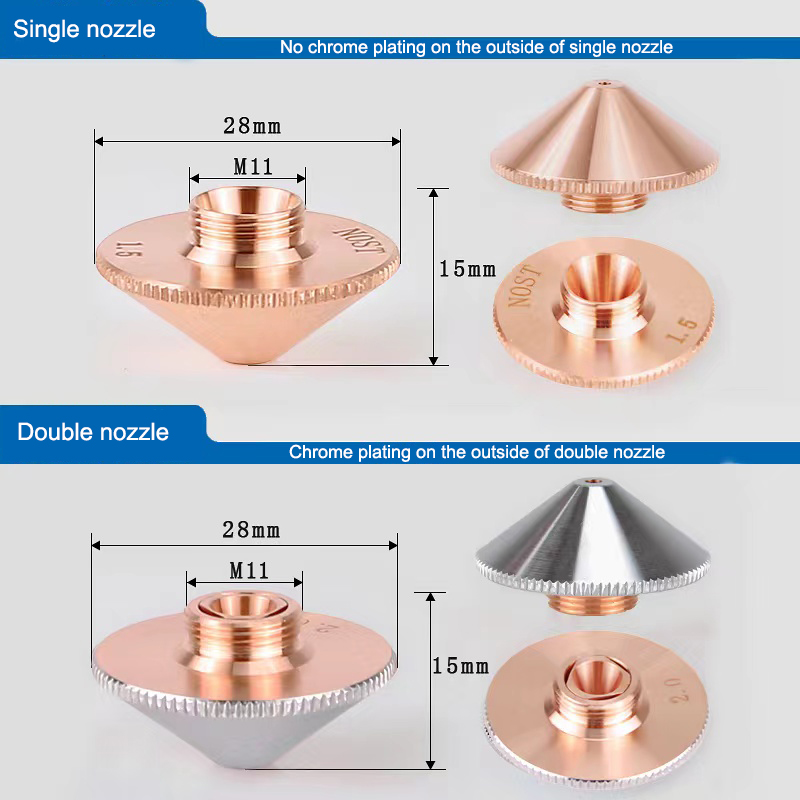

The nozzle type

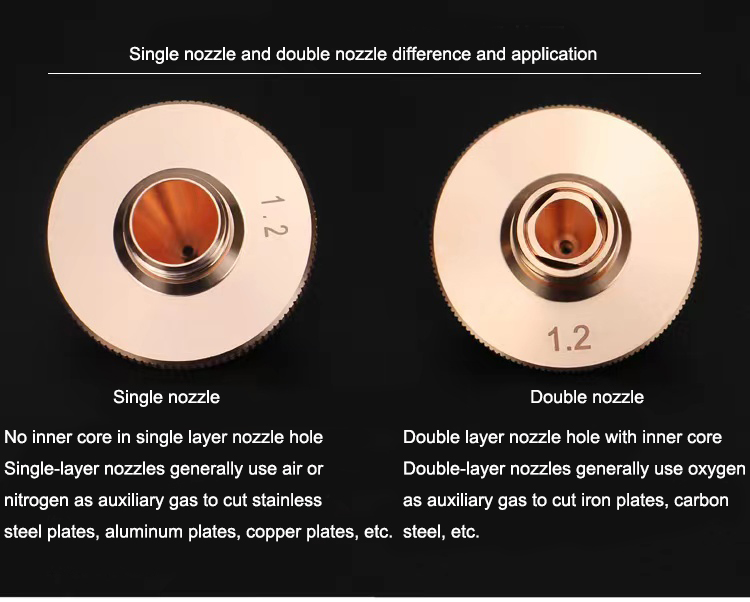

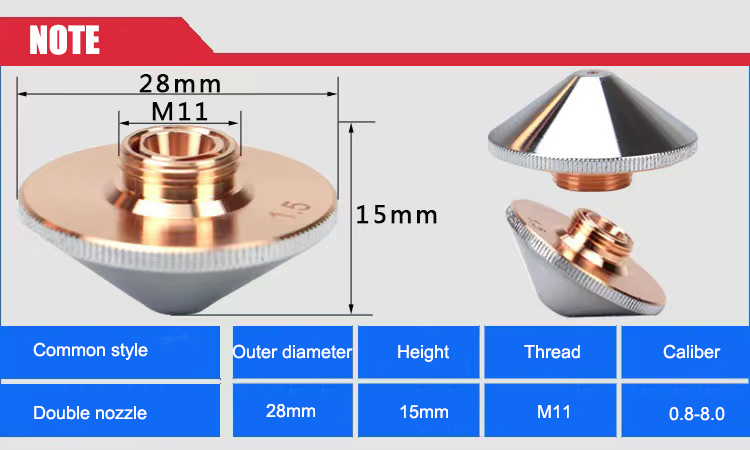

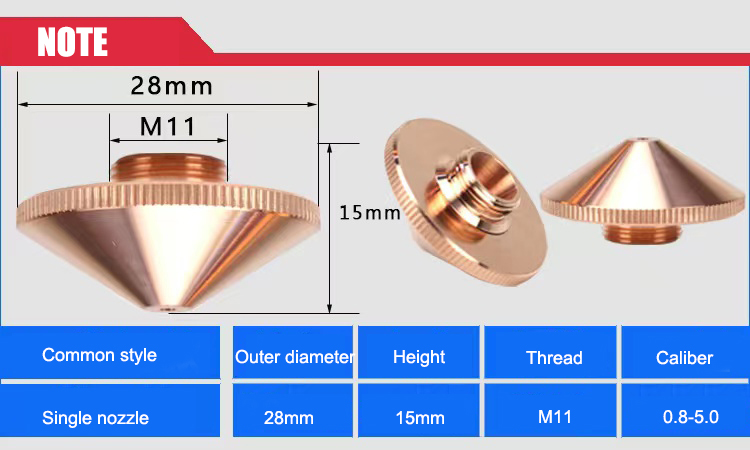

There are two kinds of nozzles: single nozzle and double nozzle.

So when we cut different materials what kind of nozzle should we choose?

Note:

When we cut 1mm carbon steel we should choose single nozzle, and when we cut more than 1mm carbon steel we should choose double nozzle.

When we cut stainless steel, aluminum,brass we should choose single nozzle.

1. When cutting thin plates (below 3mm). The nozzle with a diameter of φ1mm will be thinner, while the nozzle with a diameter of φ1.5mm will be thicker, and the corners will be more likely to have melting stains, and the gas consumption will be large.

2. When cutting thick plates (above 3mm). It is not stable to use a nozzle with a diameter of φ1mm. Because the cutting power is high at this time, the relative heat dissipation time is long, and the relative cutting time also increases. The gas diffusion area of the nozzle with a diameter of φ1mm is small, so it is not stable, but it can basically be used. However, the nozzle with a diameter of φ1.5mm has a large gas diffusion area and a slow gas flow rate, so the cutting is relatively stable.

3. When cutting plates with a thickness of more than 10mm. At present, nozzles with a diameter of 2mm or more than 2mm are generally selected.

Operation Tips:

To adjust the correct position of the laser cutter nozzle:

Before each plate cutting, check whether the laser is in the center of the nozzle. If the focused light is not in the center of the nozzle, adjust the coaxiality.

The commonly used coaxiality adjustment steps in production are as follows:

(1) Coat the end face of the nozzle of the laser cutting machine with the color of the ink pad, and then stick the self-adhesive tape on the section.

(2) Punch holes with a power of 10-20 watts, observe the phenomenon, and then take out the white sticker, being careful not to rotate its relative position.

(3) When the difference between the nozzle position and the laser center is too large, the center point will not be printed.

(4) Try to hit the center point. When it is sometimes large and sometimes small, please pay attention to whether the conditions are consistent and whether the focusing lens is loose.

(5) When the center point is not in the center of the nozzle of the laser cutting machine, the adjusting screw can be adjusted repeatedly until the process requirements are met.

+86 18615585751

linda-service

C1, Floor 3, Shuntai Building, Gaoxin District, Jinan City, China